Brand Name: FS Metal

Place of Origin: Henan, China

Shape: Lump, Grain, Powder, Brequette

Chemical Composition: Si, Fe, Mn, Al, C, P, S

Size: 0mm~10mm, 10mm~50mm, 50mm~100mm, 100mm~200mm

Purity: Si≥75%

Package: Ton bag or customized according to customer requirements

Applications: Steel Making, Casting, Deoxidizer, Reducing Agent, Alloying Agent, Nodulizer

Price(USD): 1100 ~ 1800

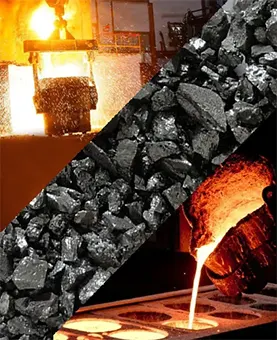

China is currently the largest exporter of ferrosilicon 75 and has many domestic ferrosilicon 75 manufacturers because of its resource advantages. Ferrosilicon 75 is rich in elemental silicon, which makes it widely used in steel making and casting, two industries that rely on elemental silicon. Japan, South Korea, India, Vietnam, and other Southeast Asian countries are the largest users of ferrosilicon 75, and they import large amounts of ferrosilicon 75 from China every year to sustain their domestic production. Ferrosilicon manufacturers process Ferrosilicon 75 into different shapes and particle sizes in order to make it meet the needs of their customers, the common shapes are mainly lumps, grains, and powders. In order to enhance the benefits of the manufacturers, the manufacturers will crush the debris generated during the crushing after grinding, add other alloy powder, and through the pressing equipment, press molding, using 1500 ° C high-temperature calcination, so as to effectively reduce the internal impurities, processing, and production of ferrosilicon 75 briquettes.

Ferrosilicon 75 is a kind of Si≥75% ferrosilicon, which is a high-purity ferroalloy product, and it is widely used in steel making and casting. Ferrosilicon 75 is mainly available in particle sizes of 10mm~50mm,50mm~100mm,100~150mm, etc. It is suitable for a variety of electric furnaces. Quartz stone, charcoal (reducing agent), and iron scrap are the main raw materials of ferrosilicon 75. To produce high-purity ferrosilicon 75, the raw materials must be strictly screened, quartz stone requires low ash and few impurities, and the choice of high-quality charcoal can better reduce the silicon in silica in silica, thus producing ferrosilicon 75 with the high silicon content.

Freshly produced ferrosilicon 75 is called "natural lumps", its size is large, about 100mm~200mm on average, so in order to facilitate packaging and transportation, the manufacturer will crush ferrosilicon 75 into uniform-size lumps according to the user's requirements. Some users will require the more uniform size of ferrosilicon 75, so it needs to be crushed manually, and then filtered through a sieve, and the qualified ferrosilicon 75 will go directly into the tonnage bag through the conveyor, while the unqualified ones will be reworked for secondary processing.

| Model | Chemical Composition (%) | |||||

| Si | Mn | Al | C | P | S | |

| Ferrosilicon 75 | 75.0-80.0 | ≤0.4 | ≤2.0 | ≤0.2 | ≤0.035 | ≤0.02 |

Reduces the oxygen content of the steel molten.

Reduces the number of oxides in the steel molten.

Improves the form of inclusions in the steel molten.

Make the impurities in the steel molten floating on the surface of the steel easy to clean.

Improves the purity of the steel molten.

Improves the flowability of the molten iron during casting.

Improves the toughness and cutting properties of castings.

Promote the breeding effect in the casting process.

Improves steel fluids purity.

Effectively reduces oxygen in the steel fluids.

Reduces oxide generation.

Improves steel fluids flow properties.

Has a thermal insulation effect.

Reduces impurities in the steel fluids.

Improves the toughness and cutting properties of steel fluids.

Packaging Method: Jumbo bag or customized according to customer requirements

Delivery Time: 7-28 days.

We offer free samples for those who are interested in purchasing Ferrosilicon 75, but you will still pay a shipping fee. You can prepare the required sample specifications in advance and contact our customer service.

We support 30% advance payment by TT, balance against copy BL and other payment, If you want to use other payment ways, please contact us.

We will prepare for shipment according to the customer's order, and we usually ship within 7 working days and inform the customer of this news in a timely manner.

We provide 7X24X365 online service, our technical engineers will be the first to help you solve any problems you encounter while using, and will record and follow up on the problems you encounter while using.

Contact: Jack Cheung

Email: [email protected]

Tel: 8615670022058

Add: Qugou Industrial Zone, Anyang City, Henan Province,China